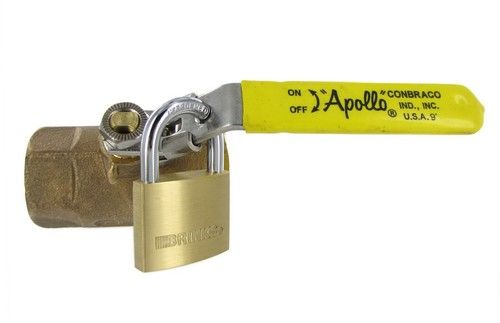

Floating Ball Valve

Product Details:

- Usage Industrial Usage,Water Industrial Usage

- Product Type Floating Ball Valve

- Color Blue

- Click to View more

Floating Ball Valve Price And Quantity

- 100 INR/Piece

- 1 Piece

Floating Ball Valve Product Specifications

- Floating Ball Valve

- Industrial Usage,Water Industrial Usage

- Blue

Floating Ball Valve Trade Information

- 1-7 Days

- All India

Product Description

floating ball design for low torque and increased cycle life. These rugged ball valves are ideal for industrial applications.

The floating ball valve utilizes natural line pressure to press and seal the ball against the downstream seat. The line pressure is exposed to a greater surface area - the entire upstream face of the ball, which is an area equal to the actual pipe size.

End Connections: - Flanged End, Screwed End, Socket Weld End, Butt Weld End and Wafer End.

ISO Top Details as per ISO 5211 / End To End as per standards BS 16.10

Design standard API6D EN17292 (BS 5351)

Features & Benefits

Investment cast body construction.Blow out proof stem

Anti static device.

Two-piece split body design

Double body sealing provided (O-ring, Gasket )

Fire safe in compliance with API 607

Direct Mounting of actuator for sizes 1 inch and above

Unique Gland sealing arrangement

Bearing provided on top to minimize O-ring wear/tear.

Specifications:

| Test Pressure In Bar | |||

| Pressure Rating | Class 150 & 300 | ||

| Hyd. | Shell | 30 | 78 |

| Seat | 22 | 58 | |

| Air | Seat | 6.2 | 6.2 |

End Connections:

Flanged End, Screwed End, Socket Weld End, Butt Weld End and Wafer End

ISO Top Details as per ISO 5211 / End To End as per standards BS 16.10

Design standard API6D EN17292 (BS 5351)

Materials:

Body, Ball & Seat: WCB/CF8/CF8M /Others On request

Seats & Seals: PTFE/RPTFE/PEEK/CFT/Others on Request

End Connections: Flanged End

Codes & Standards:

End To End as per standards BS 16.10

Flange details as per ANSI ( B16.5 )

Testing standard BS 6755/ EN 12266 - Part 1

ISO Top Details as per ISO 5211

Other Information :

Minimum Order Quantity: 1 Piece

Delivery Time: 1 WEEK

Packaging Details: WOODEN BOX